A Marker is done and applied using the graded pattern pieces to create and plot a blueprint that is highly efficient for the cutting part of the production.

Here is what a marker maker does once a company is ready to proceed in production

- Prepare the graded pattern and separate every piece as individual pieces

- Color coordinate each size to identify them easily

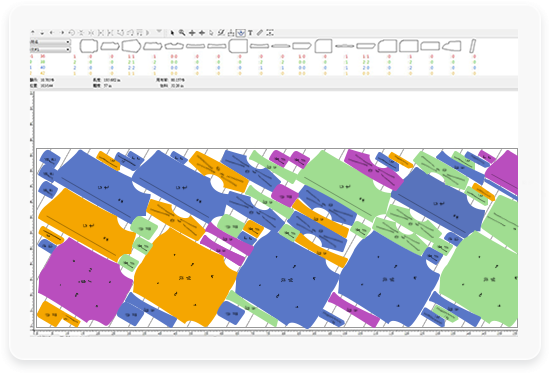

- Based on the width of the fabric, he/she will now create something that looks very much like a jigsaw puzzle like you saw above.

Mix Marker…

The factory does this to maximize and achieve the following :

- To reduce the amount of fabric needed to do the production which equates to saving money for Fabric

- Also since everything is timed and priced according to the time it takes, by paying extra to prepare the Marker the cutting will become very efficient and it will reduce the time per piece cut cost drastically.

Note, a marker will be used forever or for as long as the designer/entrepreneur decides to continue producing this garment. Even more so this is what the big picture looks like, using Jenny’s production as an example once more, the factory will initially calculate 1.25 yard per T-shirt but after doing a marker using a digital computation system by mixing pieces and placing them very close to each other like a jigsaw puzzle, it has now reduced it to .90 yard. Another word instead of requiring 312 yard to do jenny 300 unit tee shirt production, Jenny can now only allocate 225 yard.

HOW MUCH DOES A MARKER COST?

The price for a marker also resembles the cost structure for grading. The type of establishments we’ve discussed who offers the service like grading depending on diversity and capability price will vary. Traditionally charges are between $75-220. Like everything else another one of the perks working with factories on AVmade is that almost all factories on our platform waive this fee as well.

HOW MUCH HAVING A MARKER SAVES?

Let’s show you some major saving when an apparel factories does a marker

(1). If the fabric was let’s say on an average $6 then it is a saving of 312-225/y = 87yards saving x $6 = $522 in saving.

(2). If there is no marker then it would normally take about 5-7 hrs to cut. & based on the industry hourly average a factory or cutter charges are about $75/hrs. Which would mean without the marker a cutter would charge at the least 5hr x $75 = $375. But since a marker is available the time it will take to slash drastically is about ⅓ which means 2hr x $75 = $150. Saving you another $125

Now, unless we are talking about mass production, The factory usually makes something called a single marker as most startups or small companies run a small production. If the quantity is much larger than the factory will do a more elaborated Marker. This is determined based on the number of pieces that need to be produced in the variation of sizes requested to produce. Let’s proceed with the previous example of Jenny’s Tee shirt that was graded. Now she requested for the factory to produce 250 units with the following breakdown of,

[ XS: 50] [ S: 50 ] [ M: 50 ] [ L: 50 ] [ XL: 50] (this is just an example, the breakdown is up to the designer).

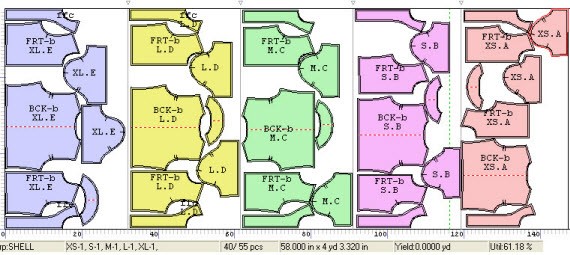

So in order for the factory to cut Jenny’s tee-shirt more efficiently, they will create a single marker that will look something like this

Single Marker…

Remember manufacturing pricing always has to do with the amount of time needed per each part of the manufacturing process as stated earlier. So paying extra for such things like a Marker in order for the factory to be efficient and expedite the process of cutting will save you lots of money on the backend as per piece cost will drop.