Ready to get the ball rolling? Great. We will discuss how to think about the clothing manufacturing process when creating or scaling your brand. If you are an entrepreneur looking for manufacturing clarity, we hope this takes your knowledge to the next level. If you’re starting, we highly suggest you check out many of our how-to courses as they will broaden your understanding and give you the full picture necessary to build your brand.

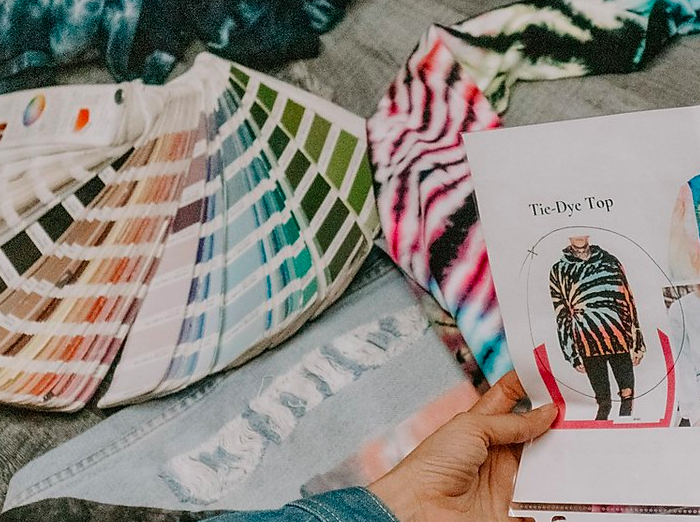

We will begin by assuming you either have your concept in the form of a tech-pack, pattern, or sample and are ready to have your clothing manufactured.

Ok, let’s get it!

First, most clothing manufacturers are not vertically integrated, which means they cannot do full package manufacturing. Full package manufacturing is when the clothing manufacturer provides all production necessities to produce an article of clothing without the designer’s need to get involved. Suppose the clothing manufacturer does full package manufacturing. In that case, the first thing you will ask to be sure of is a list of services their factory offers. The list should include the following,

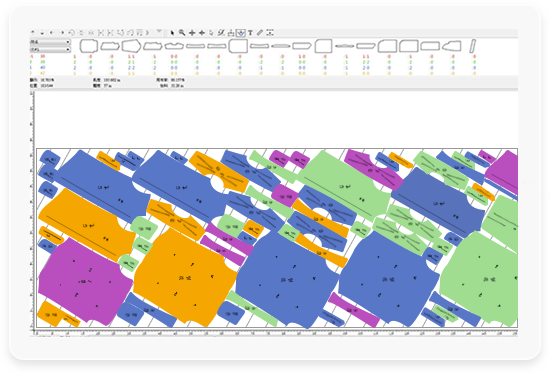

- Pattern

- Sample

- Grading & Marker

- Textile

- Dying

- Cut/sew

- Finishing

- Trims

- Main Label

- Care label

- if needed, printing & embroidery.

Although printing & embroidery are mostly s/o (send out), at least 90% of the clothing manufacturing process should be done by the factory. The remaining 10%, if not s/o, then most well-established factories will provide you with the best referrals to where you can go to accomplish it. It is important to note that all of our factory partners on AVmade.com are full package-capable manufacturers (fully integrated), which is one of the prerequisites to joining our platform.

We have listed the necessary information on a tech pack an entrepreneur must provide to clothing manufacturers. Once you have your tech-pack ready, it is crucial to know if the clothing manufacturer is equipped to do the type of garment you’re looking to make. Remember this well; every professional clothing manufacturer has a specific product they specialize in, without any exception. So if you ever run into a clothing manufacturer that says we specialize in everything, it is an immediate red flag. Please stay away from them! Our team has decades upon decades of experience, so learn all you can and carefully avoid issues that can jeopardize your brand.

There is a reason why we are adamant about entrepreneurs finding the best clothing manufacturer with specialized skills. Let’s paint a picture with an example so it’s easy to process. Mark has a clothing factory that specializes in casual women’s wear made of silk fabric. As a clothing manufacturer, the first thing Mark will do if he is well informed and knowledgeable about factory operation is the following:

- Recruit sewing operators that have a dual specialization in silk and dresses. Operators must have extensive experience making women’s dresses and be great at handling the woven fabric.

- Set production program. A program is what Mark will offer to prospective clients (designers) a list of the variable woven garment types his team specializes in and, given their capacity, the lead time they will require. So, Mark as a clothing manufacturer, can now focus on providing the best quality and lead-time manufacturing to customers.

- Set up the best-suited production (sewing) process and train the team to excellence. There are many types of production (sewing) processes such as progressive bundle, section bundle, modular, and more which we will discuss below. Choosing the right program and training the team is vital to a successful production regarding lead time or quality. Once selected, the sewing program prepares the team to work together to increase output efficiency, which means speed. It’s a win-win for all.

Conclusion! Make sure the factory is fully integrated by going through the checklist we provided above. Finally, make sure the factory specializes exclusively in the type of product you want to manufacture for quality, efficiency, and speed sake. As we mentioned above, AVmade.com factories are all full package capable and highly specialized. Check out how we’re revolutionizing for our brand partners to design and manufacture digitally.

FULL-PACKAGE CLOTHING MANUFACTURERS

In case you would like to dive deeper into full package manufacturing.

Full package clothing manufacturers are also known as fully integrated factories, are the best way to start and grow your brand. A clothing manufacturer that is set up to provide everything the fashion designer needs includes such as,

- Pattern & sample (development)

- Fabric development

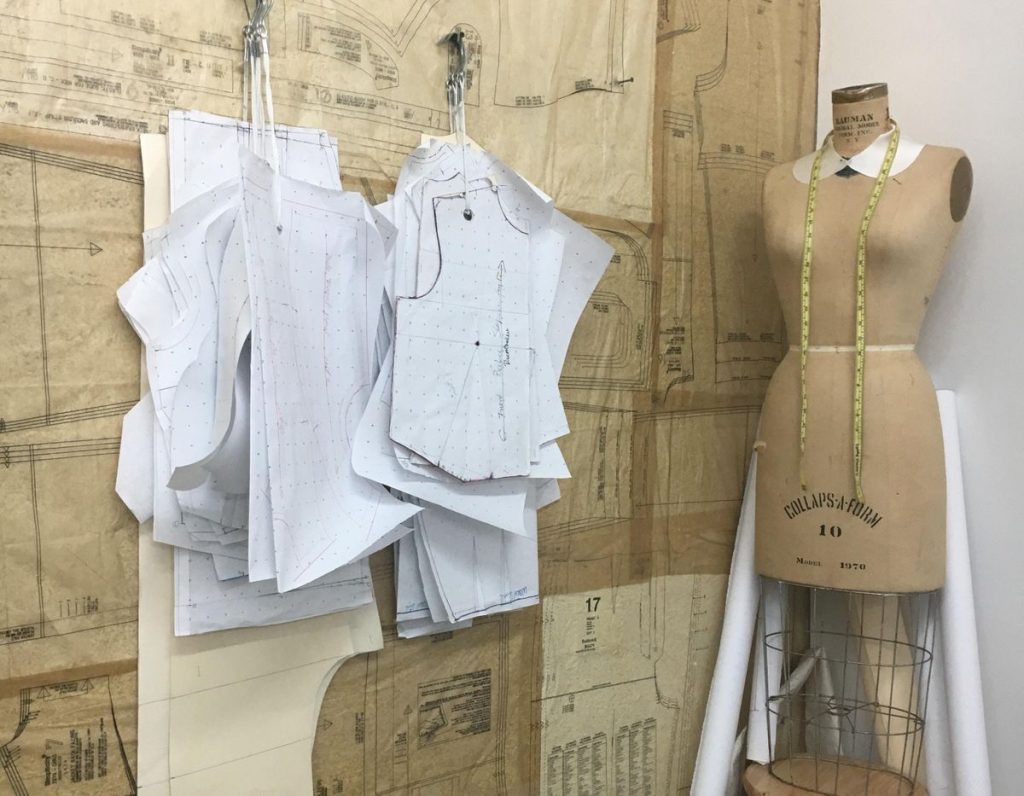

- Fabric dye

- Cut & sew

- Labels & trims

- Graphic, print, or embellishments

A fully integrated manufacturing partner is a fantastic way for designers to focus on marketing, growing their brand, and customer service. But also it reduces the chance of overspending on production and putting out a fire or wasting 80% of a designer’s time. In this way, a designer can do the following:

- Negotiate the price as a whole “simple formula.” It also eliminates the fashion designer from dealing with too many vendors in the supply chain or unexpected price increases due to a lack of resources.

- Reduce overhead. As your growth increases, so do the expenses and cash you have to advance. Hiring production managers to run around is also not feasible since that expense is something a company has to bear.

So having a reliable and well-established, fully integrated factory partner can go a long way. All this must be firmly in place early on as you develop your company. This is the fundamental step in organizing and building your brand. All clothing manufacturers are fully integrated with mass production, small-sized production run, and full package.

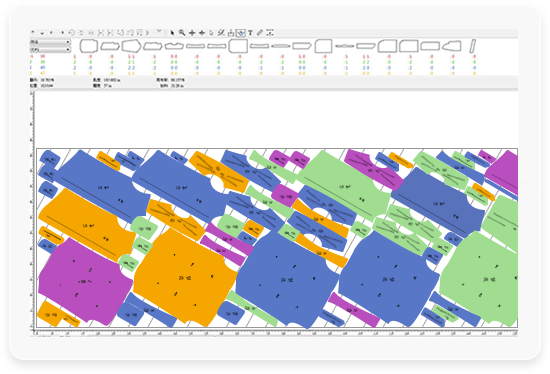

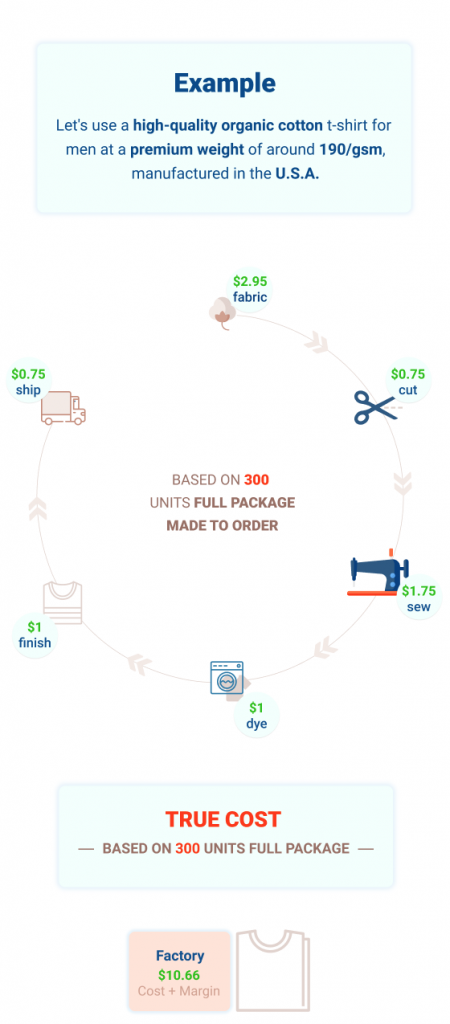

Here are the steps visually on what a full package company should do:

HOW TO FIND THE BEST CLOTHING MANUFACTURERS

AVmade.com made this complex and timing-consuming process super easy and digitally possible. If you want to know how we work, it is simple. You can either go on AVmade.com at the factory’s collection board to see what they exquisitely developed, modify it to your brand needs or send it through AV Plus for a quote. If your design is required to go through AV Plus, then this is how it works;

- Submit your idea,

- Depending on the type of style, our team will invite our factory partners that specialized

- They will then submit their bidding for full-package pricing with turn about time.

- You will select and process starting with a sample.’

There is no quick “genie in the bottle” answer if you go through the traditional route. If you are the type of person looking for a one-line reply, it doesn’t exist in the fashion manufacturing industry. There is lots of excitement that goes on when someone starts a clothing brand, and we’re fortunate to be a part of it and regularly witness when someone has entered a new chapter. Whether it means creating a brand, starting to scale your existing brand, or picking up the pace, the formula for going about this process is unique. Therefore you must be on the lookout to learn and gather information to avoid costly mistakes.

When partnering with traditional manufacturers, it is all about trial and error until you find the right fit that will best satisfy your needs. It is best to find a factory that is full-package capable and emerging brand-friendly. Also, make sure their quality and consistency are impeccable. You can ask for brand references and ask what their brand partners think.

Being excited is one thing, but most importantly, being prepared and strategic is another. No matter what you do, always remember you need to be thinking long-term, so you don’t have to grind forever. That means building a brand that will have notoriety in the marketplace sooner rather than later by avoiding mistakes and getting ahead of the competition.

If you decide to go about it on your own, make sure you at least read, and ask clothing manufacturers the questions we listed and learn as much and as frequently as possible all courses we’ve given here. It is a critical part of your journey whether you are scaling or starting your clothing brand.

HOW PROS RECRUIT CLOTHING MANUFACTURERS?

Since above we have painted an image for you to visualize, let’s give it a personal touch, shall we?

Let’s say you’ve reached out to factories that you googled or were referred to. You are in the market to find a manufacturer of leggings of as excellent quality as Lululemon. While researching, you came across someone named Alex, and you asked if Alex did high-quality leggings, and Alex responded by saying ‘yes. Suppose you are new and haven’t had the experience of how the process works. In that case, you will be ecstatic to begin producing with Alex, right? While a seasoned entrepreneur would ask for further information like,

- What is the type of clothing your factory specializes in?

- What is your production system?

- What is your monthly capacity?

- Do you do a full package?

- Are you set up to do small runs & how?

- How long have you been in business?

- What are the quality control measures (AQL)?

- Who are some brands you work with, and so on so forth?

Then follow up with additional questions if he answers everything to your liking.

If at any point, his answers do not align with your project, then you know immediately Alex is not the right factory fit for you. If you tell a clothing manufacturer what you’re doing straight away, he may agree to work with you because,

- Reason 1. You’re a natural bait, and he can overcharge you or, worse, send the job to his buddy who produces what you need while Alex makes a nice commission.

- Reason 2. Currently, Alex is slow and desperate for work, so he is willing to experiment with your job; ouch!

- Reason 3. Alex lacks focus and efficiency like many small business owners. If that’s the case, Alex will always say ‘yes’ to all things clothing manufacturing-related, which ultimately will lead to a poor quality garment. These types of contractors usually will be rated a star or two in the overall performance.

If you run into a clothing manufacturer that sells their service using any of the above bullet points listed, thank him for their time and keep searching. When you don’t have extensive industry experience, it is tempting to rush into decision-making, so be on the lookout not to make that error.

Also, do not assume because you went to visit a potential factory and see a production facility that seems to have sewing staff and sewing machines as a sign they have the process down to a rhythm that spells success or efficiency. You have to do more than judge the book by its cover.

Generally speaking, in terms of cost, every clothing manufacturer calculates their price per piece according to their time to produce the item. Suppose they have expert sewing operators who are accustomed to sewing those specific types of styles. In that case, the time required for those pieces will be significantly reduced—therefore giving you a more significant margin and a more competitive market advantage.

When looking at the quality and lead time needed, a specialized clothing manufacturer will make a huge difference. It’s also necessary for the clothing manufacturer to focus on a specific product as streamlining the factory will become highly efficient. Which ultimately means the clothing manufacturer makes more money, pays employees a fair living wage without breaking the designer’s bank or cutting corners in their business.

AVOID OVERPAYING CLOTHING MANUFACTURERS

The only way brands were able to avoid this before AVmade.com or AV Plus was to hire experts in their team who are knowledgeable. That is quite hard to do and unattainable for most emerging brands, so AV Plus was born. We have built an extraordinary database of the elite clothing manufacturers in the USA with their specific specialties for the past ten-plus years.

Just a little background on us, our executive team has decades of experience in the overall fashion industry and clothing manufacturing. We’ve launched thousands of brands, growing many into respectable multi-million dollar companies. Our executive teams are entrepreneurs of all types who can relate to the hardship emerging brands go through. We are a team of,

- Previous brand owners

- Previous factory owners

- Previous executive of various position

- Previous executive

- Software engineers

- Original bootstrappers and grinders 🙂

We’re missionaries, and our goal is to inspire and empower emerging brands. We have explicit knowledge and excellent relationships that stretched for over a decade with all the clothing manufacturers on AVmade.com. We have implemented and perfected a Kanban system for our factory partners to thrive on speed, quality, and building their business.

We only recruit and work to perfection factories that are the best in the USA with high standards in quality and performance. Our initial prerequisite is that clothing manufacturers must have a background working with designer brands, specifically in the contemporary fashion sector (not merch or low-end manufacturing). On AVmade.com, there are thousands of high-quality styles pre-developed in collaboration with our factory partners that you can modify as you wish. Our design studio has customization you can apply such as,

- Fit

- Fabric types, 500+

- Fabric weight

- 5K+ Pantone TCX colors

- Dye treatments

- Digital Printing

- Silkscreen Printing

- Embroidery

- Label

- Kind of dye (organic, vintage)

And much more, plus the ability to do low MOQ and many more flexibilities to save you time and money. No middlemen are allowed on our platform. If you haven’t found what you’re looking for on AVmade about the type of garments you were thinking of producing, then visit AV plus our full package production. Fill in a quick form to let us know what you are looking for. We’ll then invite the factories to bid and send you a full package pricing.

We feel emerging brands have a huge disadvantage and inability to compete because they lack massive capital. In return, it makes starting a clothing line very inefficient and the process costly. Nearly all small business owners are vulnerable to making mistakes which in return will either lead them to scramble and get justify behind or close shop. We, as founders, can very much relate as we had to work day and night to build what we have without much capital and funding in the beginning. As a result, we want to give emerging brands the competitive edge they need and the ability to move while maintaining their integrity and quality.

Today in the age of technology, customers expect quality products made in the USA. Our clothing manufacturers are known for their superior quality, sustainable and ethical production process, and locality. Customers also want better pricing and avoiding all the middleman markup in the past was the norm in the apparel industry. In addition, it is critical today that transparent, sustainable, and ethically made clothing manufacturers and brands are part of all great companies’ mission to stay relevant and competitive globally.

SMALL ORDERS CLOTHING MANUFACTURERS

Finding a reliable and high-performing clothing manufacturer to take you seriously when you first start is difficult. But finding a clothing manufacturer to take you seriously when you first begin, plus do a small batch with high-quality AQL to help you get the ball rolling, is nearly impossible. It is almost impossible for a well-operated and quality-driven factory to do both large and small production processing. But we have solved that issue by creating a Kanban system that we’re constantly improving, which is a win-win for both our factory and brand partners.

First of all, before AVmade, it was not practical for clothing manufacturers. On the same token, it is costly to run small production as an entrepreneur since many clothing manufacturers charge an arm and a leg. Therefore, most clothing manufacturers outside of AVmade.com, you’ve may have noticed, they won’t accommodate, or their price is unbearable.

The reason why doing a small batch order, in the beginning, is critical;

- Reduce inventory

- Maintains cash flow

- Give founders the ability to spread their bets, which gives them the ability to do a case study on the product before doubling down on larger quantities.

The reason why most clothing manufacturers won’t run a small production or will charge an arm and leg is due to the following;

- Generally speaking, factories continually optimize for higher output and better gross margin, whether a clothing manufacturer uses a progressive bundle system or unit production system. There are many steps and setup requirements before starting production. The clothing manufacturer needs to;

- Train the sewing operators to work as a unit to increase performance, quality and stay cost-effective.

- When the order is small, it’s impossible to keep it profitable or for the well-established factory to part take in a job that doesn’t make economic sense.

- Most clothing manufacturers have a large and established client, so taking on someone just starting is not worth the effort. Most small companies struggle while going through the learning curve before they pick up momentum. Most clothing manufacturers see this as a negative signal not to risk their time & capital. They instead wait until these brands become more established before they cut a deal. It’s natural why you would take this approach as a business owner, especially since 70%+ clothing brands fail. But unfortunately, the bootstrapping entrepreneur gets justify with a poor choice that breaks their wallet or brand.

- Must have a program. A well-established factory needs commitment and consistency of programs from the designer. Program means;

- If you reach out to a well-established and professional factory wanting to do 1000 t-shirts, the best clothing manufacturers will want to know how frequently you will produce and what your projections are for the next 12 + months. In this case, they can set you up in their production planning schedule and reserve a slot for your brand.

- If you are an emerging brand or just starting a clothing line, it is hard to determine your production frequency and growth projection. If you force the process, there is a high risk of you having an overwhelming inventory. If you also lack follow-through, the clothing manufacturer will opt-out on the next cycle, or you will be given a very obscure deadline. In that case, they will use you as the “JIC” (just in case) brand. If the factory production line gets slow, they will put your work order in, which means lead time can double or triple the norm.

Based on our expertise and experience for over a decade, the A-Team solved this issue. We experimented for years and finally were able to perfect it by creating a Kanban system for our factory partners to build on top of and our brand partners to breathe. Our goal is to see both our brand and factory partners succeed by;

- Joining as one unit in our mission inspire and empower entrepreneurs

- Surpassed the traditional clothing manufacturers strategy and created our own

- Go full-stack tech-based design and manufactured digitally

- Give brands leverage over corporations

- Reduce risk for our factory partners not having to put all their eggs in one basket when working with large corporation

- And we’re just getting started.

We run with an end-to-end system that keeps our factory partners constantly busy. Also, our brand partners are now happier than ever, not having to worry about the price, excess inventory, and the hustle-free process.

Let’s give you one crucial example of our customer experience. Vicky came to us as her last resort crossing her fingers that we could help. She wanted to produce four styles averaging between 100 units per style.

- Option A: She had spoken to a few well-established clothing manufacturers prior, and most clothing manufacturers required a minimum of 300 units per style. It meant that if Vicky had no choice, she would have to produce 1200 units, 800 more than she needed. Although this won’t be a big run for large clothing brands, someone like Vicky means high risk.

- Option B: Vicky spoke to a few brokers to learn that she needs to provide everything since they can’t do a full package. Also, their product price is higher by 200-300% compared to the factories she spoke to. It is common for brokers to boost rates as they deal with lots of operational overhead and add on top of factory pricing. Unfortunately for Vicky, this also means working at barely any profit. For the sake of getting the ball rolling, she was considering it until we came into the picture.

Instead, our approach looks something like this:

- Option C: We were Vicky’s last resort when she came across our platform, hoping to find a better option to manufacture her clothing before going with option B. She read how we work and decided to take a chance. We were able to offer the quality of fabric better than she thought possible and she ended up paying 30% less than the established factory quote with the MOQ she wanted. Today Vicky runs a successful brand with a bright future, and we’re stoked to be a part of it.

Stories like these are constant and ever-growing when customers begin to work with us. Ultimately, what we do is help customers like Vicky save

- Thousands of dollars

- Hundreds of hrs monthly

- Less overhead and staff

- Reduce risk exponentially

- Mentor you to succeed since our success and you are intertwined.

We will continue to get the complex staff out of the brand owners’ way to focus on creating, marketing, and growing their brand. Years later, most of our customers are still with us, and that is how we measure our success.

CUT& SEW SPECIALIZED CLOTHING MANUFACTURERS

Cut and sew in clothing manufacturing is a phrase frequently used in the fashion industry to describe one part of the process specialized by small mom-and-pop shops. Although a professional factory can provide a cut/sew service, they can also offer a full package service. The terminology cut & sew used to promote these small shops is easier to remember, and it is a more visually meaningful part of the process. It is essential to note a cut & sew specialized clothing manufacturers will not do or is equipped to do Full Package.

If that is the case, it means you have to provide a majority of what is listed under the clothing manufacturer checklist we’ve discussed above, which is quite hard to do and time-consuming for emerging brands owners or entrepreneurs just starting a clothing brand. Once the cut & sew clothing manufacturer receives all requested items, they will begin their work.

HOW TO START SMALL & SCALE PRODUCTION?

We always advise startups to start small and scale since we know that is the best way for a brand to reduce risk and friction. If a startup finds a clothing manufacturer willing to assist them early on with low quantity, it will help alleviate some of the inventory burdens. That is what AVmade does best; given our extensive experience and network database, we make the impossible possible. Read the article “clothing manufacturers for small orders” to learn how we manage to execute this process.

Starting Small

Starting small is critical for entrepreneurs looking to avoid mistakes early on that may jeopardize their brand’s future. We all heard the saying, inventory kills! The truth is, it does. In the example we gave about Vicky’s brand of “clothing manufacturers for small orders,” not all stories end well. We have seen many brands that went all-in against our advice to only learn the hard way. The fact is that unless you have built the bases for your brand to thrive, you have no business investing 10’s and 100’s of thousands. That type of investment will likely flourish once you have gone through a proof of concept and have high demand. Otherwise, it would be best to look at all your new product launches as a trial until you gather data. It means you should;

- Create a few pieces,

- Test to see what works, and

- Double down on that. It’s that simple.

Reasons like your parents loving your idea or your friends telling you how cool, are not proof of concepts. Proof of concept is selling out the 75 units you have manufactured and having 50 more customers on the waitlist. You can even survey your demographic market to find out how many people would no question love to commit before doing any production. That is a proof of concept worth doubling down on. Once you go through that process and sell out the 75 units, you can now have your clothing manufacturer do a higher subsequent run for replenishment. To assess how much to replenish, you can look at data such as,

- The number of customers’ requests

- Presale, if any

- Waitlist

- Forecasts like future sales based on part sales and so forth

A strategic approach gives you the chance to have a controlled experiment, and even if it doesn’t work, you can try again. Entrepreneurship is all about surviving until you connect the dots and set up a winning formula for your brand.

The A-team is all about ensuring our brand partners avoid pitfalls and mistakes while our factory partners produce quality and grow as a community. Entrepreneurship is a challenging and lonely road; some will take six months and others two years to build brand momentum, but giving every entrepreneur a fair chance is our goal. The “A-team” has done it a thousand times over, and no one knows this process better than us, so if you need any advice or Q&A, we’re just a chat away.

Scaling

Believe it or not, having extensive growth and demand for your product in the fashion industry does not equate to building a successful brand just yet! You need the best clothing manufacturer in place who understands and knows how to help scale and fulfill your brand’s demand cost-effectively and on time. Do you know how often a brand has spent time and energy to build momentum and pre-sold only to find themselves having to return thousands and even hundreds of thousands of dollars back to customers?

The reasons vary, but here are a few:

- A lack of experience

- A lack of staff or support

- Inability to produce the goods

- Not finding a clothing manufacturer that’s the right fit

- Poor quality after spending tens of thousands to manufacture SMH.

It truly breaks our heart when we hear these stories. It happens more frequently than you think; to give you a few customer stories: let us use the pseudonyms “Jim, Rebecca, Bob, and Julie” for the story’s sake, shall we?

- Jim worked with a clothing manufacturer here in the states who said yes to the job and opt-out at the last minute since the factory committed to another brand while Jim was still in the pre-sales mode.

- Rebecca’s clothing manufacturer, located in China, was paid prior but delivered 3 months after the due date. All customers requested their money back and never returned. Thas was over $30K worth of offers and lost close to over 500 clients.

- Julie’s clothing manufacturers shipped the goods from overseas. After spending over 45K on manufacturing, she found out the clothes are unsaleable due to horrible quality conditions.

- Bob’s production was stuck in customs for months, and after 2 extensions, Nordstroms decided to cancel. That was a 200K order.

We have heard horrifying stories from brands on how factories delivered,

- The color of the sleeve does not match the body

- One sleeve is shorter than the other

- Size XS and M are the exact fit

- The style is not at all what was sampled or discussed

- The fabric is garbage

- And the list goes on and on

Even if everything is planned accordingly with the right clothing manufacturers, things can go wrong. Large and established companies run into this issue when demands spike unexpectedly or when things go wrong. Since most established brands have an army of production managers trained to stay on top of it and look for these issues, they will over-prepare and executed. This results in having a better chance of solving this more efficiently than you and your team of five when push comes to shove. We’re adamant about you reducing risk. Still, there is always a risk involved, but ultimately, you need AVmade “A-team” to make the impossible possible.

To give you an example of how we help a startup brand overcome issues even after being well-capitalized and venture-backed. For privacy’s sake, let’s call this brand “1A”.

- We met 1A to do price exercising and work on production planning. Their goal was to launch in mid-March for the spring season.

- Their projected quantity was approximately 2,000 units per style based on their data on their MVP (minimum viable product), a fancy name for proof of concept. Most of their data were based on the number of people on their waiting list to determine projections.

- They planned to do 10-12 styles to start and were looking to run a program of bestsellers around 15,000 units monthly after the test pilot.

- Before they launched, over 15,000 units were produced and shipped to their D.C. (distribution center).

- Now do not compare yourself with 1A unless you are as well-financed as they were.

- To give you a little insight, they started with a dozen team members, and the marketing department alone had 6 members and spent six months behind closed doors working on branding, marketing, promoting, and building momentum before launch.

Then the time came for the launch date, and the flood gate was opened; within a matter of hours, everything was sold out. First, let’s acknowledge one crucial factor, their marketing teams were terrific, and also, this would never have been possible if it was not launched online. Given the number of people that came to buy, it can only be done on e-com.

The virality they never anticipated was due to shares on social media with friends. Which triggered unexpected spiked demand 4X more than what was on hand to deliver. The hyperbolic viral growth came unexpectedly and pissed many early customers on a waiting list as they could not get their goodies on the launch date.

Note, this was not pre-sold but rather heavily pre-marketed for six months before launch. Immediately they contacted us, and we were able to strategize the initial plan within a matter of hours and implement a production process in place a day later. The first thing was to let their sales team notify customers that they will begin to deliver in 15 days and complete in 30. Although our usual lead times would have been 6-8 weeks, the general industry standard is 12-20.

We worked with all of our factory partners to form a solid plan throughout the day. The following day we proposed a concrete plan and were ready to go. Our sewing factory partners, dye houses, and knitting mills came to work as one unit to complete a pre-order of 25,000+ units. We ultimately managed to meet the milestones we set and begin delivering within 13 days and shipped the last batch in 24 days, six days before the deadline. That was unheard of even for their experienced senior team members who worked for corporations like Gap and Nike.

This is the level of strategy we implement with all of our customers as their success means ours. Most importantly, our mission has always been to inspire and empower entrepreneurs. We aim to level the playing field and democratize what it means to compete, no matter how small you are. We have many emerging brand partners who started with 2-5 thousand dollars and grew their business into a $2-5 million business.

The apparel industry is a beast that can only be tamed with smarts and experts; raising capital dilutes ownership drastically and may not be worth it for a specific type of industry, which apparel may be one, at least in the early stages. In immediate terms, having a lot of money feels favorable. Still, the reality is many of our customers are self-funded and bootstrapped their business from the ground up. 98% of the time, these scrappy enterprises will eventually figure it out and take home pound to pound more money than those who raised tons of capital early on, and that’s a fact.

MASS PRODUCTION CLOTH MANUFACTURING

Are you ready for mass production? Don’t answer that question unless you have a proof of concept we’ve discussed in starting small. As a company that’s genuinely trying to help emerging brands grow, our first question will be, “Why do you think you are ready to mass-produce? But there are many factories out there that will take advantage of your naivete and perhaps insist on mass production. Only brands with proven data, a large customer base, and proper sales forecast projection should be the ones to think or strategize about mass production.

If you’re still learning who your customers are and what they’re looking for, you need to start small. It doesn’t matter about your gut feelings or how your mom told you, without proof of concept, customer base, and data, take it down a notch, please!

Whenever you are ready and choose to go through the mass production process, here are some tips to help guide you. You need to make sure you have;

- Proper demand for sales forecast

- Production strategy

- specialized factories

- production cost estimation

- gross margin

- ideal lead time

- fulfillment strategy

- employees to support growth

- Full package capable factories. Meaning the factory needs to be vertically integrated and can provide

- pattern & sample development

- fabric development & dye

- cut & sew

- label & trims

- graphic or roll printing if necessary and more

- Able to consistently run a program of large production. Both in smaller or larger quantities when needed.

- The proper capital to back it all.

As usual, this is what the A-team is here for entrepreneurs like you. When the time comes, we will have your back.

PRIVATE LABEL CLOTHING MANUFACTURERS: THE INSIDE SCOOPS

Learn which clothing manufacturer can produce private labels, what private labels are, and why even bother? Let’s begin defining first what it is?

WHAT

What is private label clothing?

Private label clothing is standard today, but it wasn’t always. Since the boom of department stores, the concept starting in the 1970’s private label became a thing to do. Since designer clothing was not affordable to the masses, department stores initially asked brands to create a cheaper version of the clothing under a bridge name to expand their market reach. As the industry snowballed, the concept has evolved.

At first glance, private label clothing is hard to distinguish, but it is self-evident once a customer feels and puts it on. Private label means finding a way to produce the garment at a much lower price point. For example,

Ralph Lauren collection denim is sold in Neiman Marcus between $500-1000

Polo Ralph Lauren at Mr. porter is soled between $150-300

Lauren Ralph Lauren at Macy’s is sold between $50-80

So depending on Ralph Lauren’s distribution channel’s customer-based, the product quality gets reduced to accommodate it. But today, that envelope is pushed to its limit; as you are aware, companies like Shein, Forever 21, and Fashion Nova sell jeans for $20. This means if you have no conscience of what goes on the supply chain to achieve these prices, then there is proof of how low those prices can get pushed.

WHO

Who are the factories that specialize in private labels?

Today a fashion designer in wholesale clothing not participating when asked to do private labeling by the department stores has a great chance of being knocked off by them. Every department store has multiple private label brands they own. They can create items they see performing in their store without involving the brand owners. These department stores range from a major corporation that has a brick-and-mortar or an online giant.

Here are two scenarios of how these two things take place; let’s use a pseudonym ‘James”,

Scenario 1: James owns a clothing brand called “A1”. It is trendy, and most people often can’t afford the “A1” brand but would buy if affordable alternatives existed.

So the department store will approach James and propose that “A1” creates a cheaper version similar in looks. They will set a steeper discount than James needs to meet. Typically that discount ranges between 65%-85% more affordable than the original price. If James’ initial wholesale price to the department store was $50 per item, they now want it for $17.50.

Typically a department store on top of the wholesale is 250-300% markup.

Scenario 2: Seeing the explosive growth of A1’s product quickly, the department stores will add it to one of their own private labels. They will primarily cut out designers like James completely, especially if the brand is a new partner. Since James has no data on how much potential demand his product has, his life simply continues. It is usual for a designer to sell the item to the department store, not knowing what happens after since there is no way to monitor their data. Some department stores will provide sales through numbers, meaning how much they sell week after week but never demand-related data. That’s why we educate customers exhaustively about the importance of building a direct-to-consumer brand.

CONCLUSION

Remember, the only thing that is trademarkable in fashion is logos and artwork. As for the artwork, if there is a 30% aesthetic difference, it’s protected under the “original art” policy. Still, any other design about the garment can be replicated legally. Nowadays, it is so much more profitable for department stores to cut out designers completely.

Today you will see this behavior widely accepted. Every time you see a product that reminds you of something else, just know it can be a private label. Zara is the best of all when it comes to knocking off luxury brands precisely without even modification. If you search within your favorite department stores for private labels that belong to them, you will notice thousands of products they carry under many of their private clothing labels.

Our advice is to continue branding yourself and to continue to do direct-to-consumer. Make sure you build your brand with the long-term in mind and focus on owning your customer data and customer loyalty without any middlemen.

It is not to discourage you from working with department stores, but just know that you have to look out for your own label’s long-term interests. Building relationships in the fashion industry is ideal, but be sure the relationships you build are sustainable.

USA VS. OVERSEAS: CLOTHING MANUFACTURERS

We have done a side-by-side analysis between clothing manufacturers in the USA and overseas in the member’s benefits section of AVmade.com. The very core differences are quality, speed, communication, and overriding cultural principles and values. Yes, indeed, this is a bit vague so let’s get technical.

QUALITY

In terms of quality, there are many ways to determine if a clothing manufacturer is set up to produce quality ranging from excellent, good, or cheap. For example, Asia has always been known, where we westerners go to get stuff made at a much lower price. In contrast, when looking at countries like the U.S., Italy, Germany, France, you will see manufacturing has always meant high quality.

The reason the Asian market has boomed in manufacturing is not due to their overwhelmingly high-quality products. But rather a demand for cheaper and cheaper products by western corporations like Amazon, Wish, Walmart, and many other brands you’ll find online today. Although people seem to catch onto the fact that quality products will,

- Last longer

- Feel better

- Do more good for social well being

- Less hazardous and harmful to consumers health

- It solved the global environmental crisis

- And so many other benefits

Still, somehow these cheap goods make their way into people’s closets out of convenience or impulsivity. The go-green approach is hard to implement for most corporations since the entire foundation is built on going fast by any means necessary. Still, consumers, in general, will inevitably become wiser and no longer support companies who practice unethical and unsustainable values.

SPEED

Customers are trained to want it now, and entrepreneurs are being pushed to do whatever is necessary to fulfill the demand.

Yes, you can draw a case to say that’s overconsumption, which is true. But if this process gets applied to cheap fast-fashion driven companies, then it’s harmful. If the production process maintains ethical and sustainable standards, but the factories can expedite the production process, then it’s a tremendous win-win. The reason for speed is because entrepreneurs have a much broader reach today, thanks to direct-to-commerce sales. Most entrepreneurs now cater to customers without needing middlemen and sell through inventory a lot faster. In other words, brands are no longer confined by the process of the past to scale.

Today a savvy entrepreneur can go from zero to a million dollars in sales within 12-24 months, unlike in the past, which requires 5 plus yrs. So speed to production is critical while maintaining the same level of quality. Most of the clothing manufacturers on AVmade can deliver a product in 4-6 weeks and sometimes less. On the flipside, overseas clothing manufacturers, just in shipping, need 6 weeks, and production lead times vary between 8-16 weeks. When looking at our side-by-side analysis, you will notice the pros and cons quickly. When there is an absence of speed, then entrepreneurs are justify with two choices.

- Which means tying up needed capital to grow. It is super risky if it doesn’t sell. It will deplete your cash flow and force you to accumulate debt. Excess inventory is one of the reasons why many businesses fail.

- Having to wait for a very long time also causes customers frustration or kills momentum.

LOGISTICS

By basic assessment of standard shipping lead time, you can realize the speed to ship difference.

- On average domestic shipments take 5 days at a standard speed

- While overseeing shipments takes on average 35-45 days at a standard speed

It’s not hard to tell what will help to grow your brand. Plus, all the

customs paperwork,

- Duties

- Clearance fees

- Cargo fees

- Trucking fees

- Brokerage fees etc.

These added costs can jack the price by 3-4x more than initial quotes. In hindsight, the price looks great, and once you calculate all logistics-related costs, its true color comes out.

The problem seems never to end; there is also a massive issue in traveling that far by using fossil fuels, which is not sustainable. Plus, any sort of electricity and fuel consumption at that level is very wasteful and selfish for companies to ignore. Issues like global warming, the CO2 crisis, and the massive extinction of sea life is a direct repercussion of long-distance massive containers shipments daily. It is evident and obvious to incorporate ethical and sustainable practices to push humanity forward and open a new era to what it means to be a founder and CEO.

We must go green as much as we can in every way to lead the world forward in the right direction as entrepreneurs. AVmade mission is to bring together like-minded brands and factories to work together for a bright future.

COMMUNICATION

When developing a product, the clothing manufacturer must clearly understand what’s expected without leaving any room for error. Since language barriers and cultural expectations can differ in meaning and quality expectancy, working with overseas factories for western brands can be challenging. Plus, it is common for overseas factories to outsource customer service and this by itself is a huge red flag. Here is what we mean:

- Language barriers. Since the languages are so different, it causes vital information to get misinterpreted. To solve this issue and monitor production quality, a brokerage operated by a western business owner is often hired. Which increases production costs somewhere between 20-30%.

- It is a prevalent practice for clothing manufacturers overseas to outsource customer service by using third-party service providers. So this involves speaking to someone whose English is slightly better but has no manufacturing experience. This friction always leads to disaster.

- It is a ubiquitous practice for overseas clothing manufacturers to falsify pricing when they promote the product’s cost. They will lure designers in with promos, then requiring a more significant quantity when negotiating starts. It is very unpleasant and irritating for us western entrepreneurs to go through this every time we order. But very common and part of an eastern trading culture.

Excellent communication always serves as an anchor to the quality of your goods, and poor communication has the unfortunate power to destroy it all. It’s a prerequisite for all of our factory partners and the A-team’s customer service/sales teams to have a manufacturing background or training and be based here in the USA.

CULTURE

Adding to our previous comments, this has more to do with how one’s mind is trained for decades than anything else. When an individual entrepreneur produces a product and brings it to market, they expect to grow their brand and create a household name. After all, building a brand requires time and money, which you can’t get back. So, for anyone who attempts to build a brand, the primary concern should be quality.

Unfortunately, the broader manufacturing sector in Asia is based on who can produce cheaper and faster. Most overseas clothing manufacturers have zero decency in respecting a designer’s hard work and have no problems ripping off designs. We usually see a few variations of this issue:

- Cultural difference. Culturally what we consider quality is very different. You have to remember, we sent production to China to be cost-effective, not to improve quality. Therefore for the past 60 years, we have thought overseas companies to be cost-effective and produce goods with price in mind rather than quality.

- We’ve all seen headlines stating larger companies like Gucci, Louis Vuitton, and so on, losing an aggregated trillion-plus in yearly sales. But even though the general market doesn’t see it, industry experts can tell you small businesses face the same issue. Small to medium-sized companies, which account for 90%+ of local companies, regularly deal with their product being knocked off. This frequently jeopardizes their business and financially harms them when producing overseas. Sadly, Knockoffs are done mainly by the same clothing manufacturers that produce your goods in Asia, who now have precise data on your product demand. They use that data to turn around and cut a deal with a much larger corporation. Suppose you are producing 10,000 units a year, for example. In that case, the giant corporations can quickly take 250,000 units and get very steep manufacturing discounts which are a win-win for both the factory and department store. But ultimately, it means they can not cut your price substantially and move you out of the picture.

- Except for Japan, most overseas clothing manufacturers have been taught not to care about quality and focus on quantity for generations. Sadly, this mindset has taken hold due to cost and price being the priority by large corporations in the west.

In some customer examples, we’ve heard designers asking for an order of 100% Pima Cotton t-shirts, and they received 50% cotton / 50% poly t-shirts instead. When confronted, the usual answer is ‘well, it’s not that different, smh. Unless you have your clothing manufacturing facility there like Nike, anything else from Asia will last you about a blink of time compared to domestic goods.

AVmade clothing manufacturers have a nondisclosure agreement to respect and protect all customers’ patented or copyrighted work and will never provide third-party vendors with any data.

Whether looking at quality, communication, or overall business values and principles, producing goods in the U.S. has many excellent benefits, which stagnate way higher than overseas companies. It is obvious where the future of manufacturing is heading from our point of view. We are delighted to lead the way in helping clothing manufacturers in the USA get exposure. We aim to give emerging brands the ability to compete with large companies and perhaps even outperform them one day. Visit our mission and company info to learn about us and the benefits we propose.

8 REASONS WHY U.S. CLOTH MANUFACTURERS ARE THE BEST

Why American-made clothing instead?

- Superior quality

- Custom options

- Replenishment

- Flexibility

- Pride

- Communication

- Logistics

- Time

I. SUPERIOR QUALITY

How are clothing manufacturers in the USA better?

American-made products are always going to be better quality products if you compare them with overseas manufacturing. Even though there are a few cheap manufacturers in the USA, generally speaking, U.S.-made are better than those made in China. When comparing the quality of clothing made in the USA vs. overseas, the difference can be seen;

- Attention to detail

- Material quality and feel

- Product longevity

- Stitch quality

And from the production aspect, one also need to look at how impeccable the following are;

- Fabric production. The U.S. has many government regulations and policies; therefore, you can’t cut corners like you would be able to overseas.

- Pricing is based on a living wage, not a child or sweat labor; therefore (sewing) operators are expected to have extraordinary experience and quality here in the USA.

- Laws and regulations. Are strict here in the U.S. when employing. In the U.S., businesses usually tend to look for experienced workers and compete in salaries. When it’s done overseas, it’s more about low wages and long-term contracts to lock employees at a fixed rate. Plus, there is no minimum wage to protect employees, so how low you can pay employees has no cap. Stories like factories having employees live in the workspace are true and sad. This is the dirty world of sweatshops.

- Garment dying. Given lawmakers’ many policies and frequent inspections, U.S. companies must abide by rules like avoiding dye ink with lead and other toxic chemicals. The U.S., both federal and state-level, applies policies to protect against these dangerous chemicals for health purposes. Still, overseas factories’ main concern is price, and toxic chemicals are not regulated. Even if they were to be regulated, bribing to turn a blind eye is super common and even promoted.

- Quality control. AQL is done throughout the production process, which guarantees consistency and a high degree of quality.

- End of production. The level of inspection, and again the quality, is thoroughly monitored.

- A stitch count. A 10-16 per inch stitching is the norm when U.S.-made vs. 6-8 when made overseas. A higher stitch count is better since it is a validation for quality and longevity.

Our factory partners on AVmade.com are known to have products that last. All of the quality check marks we have mentioned above are demonstrated by our factory partners.

While we are on the topic of quality, we also want to give you a heads up and tell you to watch out for some factories that may have a label that says made in the U.S. This includes some garments produced by merch factories and others who found a loophole and learned to game the system by doing the following.

- Their fabric is knitted, dyed, and cut overseas. This means 80% of the process is done overseas, but to label it “Made in the USA,” the remaining 20% is assembled here.

- The fabric is purchased overseas, but the sewing part is done here with low thread counts.

- Individuals at some factories are paid the bare minimum, and sometimes even less if they are illegally here.

- Garments produced are usually form-fitted to minimize the amount of yardage they use per item to save on the cost of fabric.

We assume there are about a dozen more tricks, but you get what you pay for. So it’s best to stay away from cheap or merch clothing manufacturers if you’re looking to build a brand.

II. CUSTOM OPTIONS

What are the custom options provided?

This one is trickier because there are many options, but specialization is spread out in the USA. Until AVmade Design Studio, there is no ecosystem built to aggregate all that talent to work together to make it possible for brands to design and manufacture digitally. A designer had to deal with multiple factories and vendors to bring their concept to life in the past. But thanks to the A-team that is becoming the manufacturing of the past. AVmade.com offers custom options such as:

- Choices of Pantone TCX & TPG colors, which means 5,000+ colors to dye

- Any size break of your choice

- Fit iteration

- 100’s of fabric types in content and weight and expanding daily

- Wire range of dyeing such as organic, reactive, pigment, and so forth

- A wide range of fits and the ability to modify them

- A wide range of main label types for your brand

- Custom handworks like ombre and tie-dye

- Any type of printing

- & much more

Nearly all of the factories on AVmade.com do all of the customizations listed above and more. You can modify the product, apply any. Customization and work with various factories with no middlemen. Everything is transparent and displayed before you, including pricing and MOQ.

III. REPLENISHMENT

How is replenishment better?

Replenishment is like production. Working with a clothing manufacturer that produces made-to-order means getting what you want, for as long as you want, with any customization choices. There are no limits, restrictions, or production hiccups (within reason, of course) when working with a highly professional factory in the USA.

But if you have ordered from an overseas or merch clothing manufacturer and want to replenish the item? Well, they may be sold out, need higher Moq now, or discontinued the fabric, or perhaps can’t help you right now.

Ultimately, it means if you work with factories that are inconsistent and unreliable, then you will build a clothing brand that is inconsistent and unreliable. At AVmade, the sky’s the limit, and the factories we partner with have to be;

- Full package capable

- Offer Made-to-order

- Offer low MOQ

- Able to do nearly all customizations

- Able to always receive reorders with no exception.

It’s that simple!

IV. FLEXIBILITY

How flexible are clothing manufacturers in the USA?

The ones who have reached the elite status as factories in the USA can do what their customers want and how they want it done. Flexibilities are the same as customization options that we have discussed above. Because many new things come to market all the time, the best factories are constantly on top of it all. For example, many new technologies that were developed are offered by our factory’s partners. Such as;

- Antimicrobial finishing

- Dry wicking

- Organic dying

- Recycled fabrics.

Plus, our engineering team makes it possible for you to design and manufacture digitally.

V. PRIDE

How does pride help?

Okay, this idea can be misunderstood easily; just to clarify, before we get going, we are not talking about wrapping the American flag on your head and beating your chest like a primate. An entrepreneur trying to build a brand and works hard to do so would always love to see their customers speak volumes of their brand.

This form of appreciation usually comes with customers supporting your business and giving you a push forward. When you put the best product out and feel highly confident about who you are as a brand and what you stand for, you’ll reap the benefits of your customer base as they feel proud of owning the product your brand makes. You can simply relate to this by looking at your wardrobe and seeing which products you own make you feel that way. You will always associate feeling good whenever you wear that brand. Every business owner dreams of this type of pride, but you can only achieve this by producing a quality product. Take pride in your products to continue to build a brand with longevity while customers become volunteer brand ambassadors. Now, that’s pride!

VI. COMMUNICATION

Why are communications critical?

Talk is cheap if the listener doesn’t understand the message. Communication is the most critical part of any process, whether it’s business or personal. Even when two individuals speak the same language and try to put their best effort forward, information can get lost in translation.

American-born and Chinese-born individuals with minimal exposure to each other’s native language can communicate, but a hail Mary is attached. You need to pray that overseas clothing manufacturers will conceptualize your message regarding intricate details; unfortunately, to make matters worse, most of these factory employees and owners don’t have a basic education. Which significantly increases the risk for error.

Those who have experience using platforms like Alibaba know what we mean. 90% of the time, the products turn out to be a disaster, and the other 10% of the time, when certain expectations are met, it’s truly by force of a miracle. As usual, the only reason large corporations like Nike have managed to get the production overseas right is due to having factories of their own. Plus, they have an army of teams from the west as execs who oversee operations.

You are no Nike and represent the other side of the coin. When dealing with small factories in China, remember they are the mom & pop shops, middlemen, hustlers, and little dealers. Unless you are a multi-million dollar company with the proper infrastructure and team to build your plant in China, it will never work. Ultimately, the resulting lack of communication will inevitably be the downfall of your company.

VII. LOGISTICS

How are logistics better?

For most products made in the U.S., on average, a shipping cost is around 7% or less than the production cost value. But any goods made overseas will travel quite far and go through an extensive verification of many governmental bodies that will require various documents and fees. The price for shipment can average between 50-300% of the product cost unless you are bringing a container full. Why? Well, since the product travels such an extensive distance, you’re looking at all the different variables in cost you have to factor in, such as:

- Fob fee

- Fuel costs

- Tariff cost

- Custom fees

- Duty cost

- Brokerage fees

- Trucking fee

- Loading dock fee

- Warehousing fee

- Finally, the delivery fee to your facility

That means not only does it take so much time to receive shipments, but the cost is extremely expensive.

- To give you an example, let’s look at one of our high-end designer brand partners who used to do business in China. Let’s use the pseudonym “Stephanie” for the sake of her story. Stephanie had her products made in China for several years before she found us. She was savvy enough to hire a third-party agency to oversee the process in China at 30% per item. One of her best-selling items would cost $29, excluding agency fees and shipping. When the items were shipped by boat, the final product cost would be around $49 bucks after all logistics and fees are accounted for. Also, at times when she had an emergency (like an awesome unforeseen sales spike), she needed the product faster so she would ship by air. That increases her shipping cost significantly, and it would generally be between $59-69, depending on the shipping company rate and the season.

We have discussed it more in another course, logistics & shipping if you need to dive deeper. Finally, we have noticed the common thread among small business owners or newbies just starting a clothing line. They will pay attention to the upfront cost and fail to calculate the final price. Our advice is to tread carefully and get all the costing info ahead of time if you work with overseas factories.

VIII. LEAD TIME

How is lead-time faster?

Lead time includes all the required processes from production to arrival at your warehouse. It takes entrepreneurs much longer when working with overseas partners since they spend a lot of time going back and forth for the various reasons we’ve listed above. Consider any back and forth will equate to time setbacks regarding, such as communication issues, development issues, production-related questions, shipping, and more.

Most emerging brands or small businesses need to build momentum and capitalize on their demand quickly. Also, in today’s digital era, things move a lot faster. That means every brand seeks a shorter lead time to manufacture and ship their product to meet demand.

- DEVELOPMENT

Most development overseas takes about 8-12 weeks if the back-and-forth is minimal. In contrast, professional domestic factories like those on AVmade.com take about 2-3 weeks.

- PRODUCTION

Most production overseas takes about 12-16 weeks lead time, excluding shipment. In contrast, professional domestic factories like those on AVmade.com take about 4-6 weeks.

- SHIPPING

Most products coming by boat from overseas take about 45 days; otherwise, you can have items shipped by air. Airline shipments take an average of 15 days, but the shipment cost is usually 100-200% more than usual. You’ll pay for that rapid delivery and cut your profits quickly.

As for factories on AVmade.com, usually shipping lead time is 5 days. Nearly all the shipping fees on AVmade.com are 50% less than standard U.S. postal office rates, so we pass the savings to our customers. Also, some factories will incentivize exec members’ free shipping if brands spend more than a certain amount. All in all, if made in the USA, it will benefit you in terms of quality and shipping cost and allow your brand to play a part in today’s ethical and sustainable movement.

We hope you have a clear understanding of what it is about American-made that has so many advantages for brands like yours. Putting forth a product that you could be proud of when building your brand is central to the life of your brand. If you have any questions, please contact us anytime, as we love talking to founders.

CLOTHING MANUFACTURER PROCESS & COST

Here we will discuss the main process and requirements a professional clothing manufacturer will need from a brand to carry out the necessary job. We cannot overstate the pluses in regards to a full package clothing manufacturer compared with a cut-and-sew only factory.

A full package clothing manufacturer avoids the need for designers to spend 50-60 hrs weekly running around or force to hire a 6 figure production manager to do the running around. Also, the final price will be much better if you find a clothing manufacturer that can do a full package since you can negotiate the all-in cost. Let’s begin with the core part of the production process.

- Textile

- Dye

- Spread

- Cut

- Sew

- Main Label

- Care label

- Trims

- Quality Control

- Finishing

- Lead time

- Program

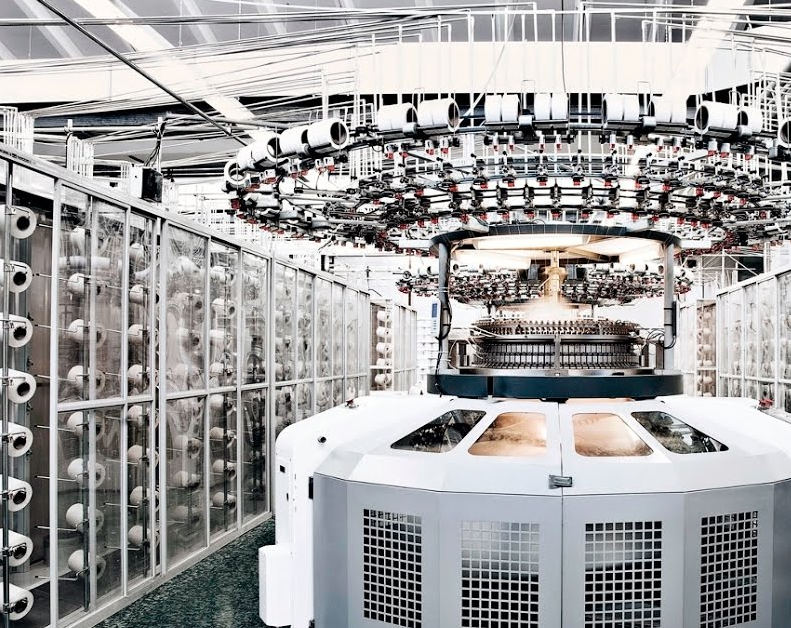

TEXTILE

TEXTILE PRODUCTION

Are you working with a,

- Full package factory or

- Cut and sew factory

To understand the difference,

- A full package factory will provide you with all your brand’s needs without having you outsource parts of your production needs.

- While a cut and sew factory will asking you or pointing you where to buy fabric and other parts of your production needs

If you are working with a true full package factory, not a poser, then let them know what it is that you need and move on. If you aren’t sure how to express your needs, then provide them with an image or a product of a garment so that they can recommend best practices. You can browse on AVmade.com, get swatches to test if you are new.

On the other hand, if your factory outsources or insources most things, then know they are not a full package clothing manufacturer. They are either a broker who outsources the work fully or solely a cut/sew factory. You can tell by visiting their factory and setup. If you have to source your textiles or trims, you can find textile mills on AVendros.com without buying from middlemen like wholesalers or retailers.

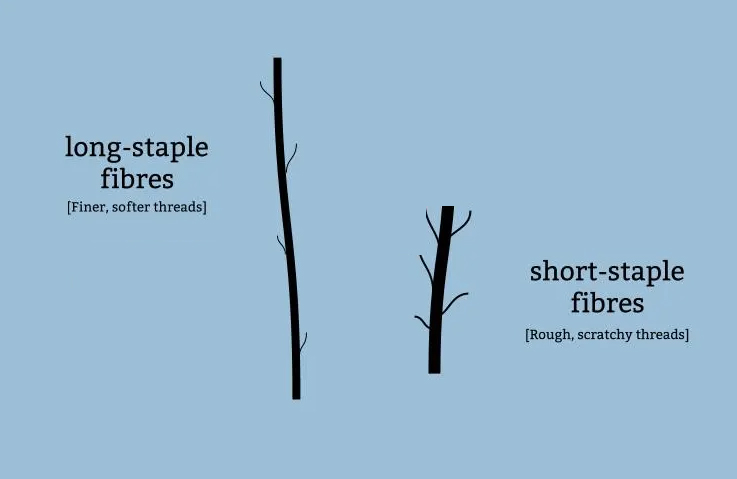

TEXTILE COST

Textile cost depends on the fabric quality & quantity you are looking for. It will also depend on the weight of the fabric and content. If you never had the opportunity to learn about clothing textiles in-depth, we highly recommend you check the ultimate clothing textile guide to become the master of your craft.

The hefty pricing markups always come from wholesalers trying to get the most margin out of the fabric. When trading outside AVmade.com, we advise you to carefully identify a wholesaler and a textile mill. Many companies pretend to be a textile mill when, in reality, they are wholesalers.

The takeaway here is if you are a designer or an entrepreneur, you should;

- Always eliminate wholesalers

- Work directly with mills

- Always focus on quality

- Always keep textile consistency

Visit the AVmade.com textile section to find the best USA textile mills you work with directly. We provide a direct-to-consumer service with customization abilities focusing on high-quality made in the USA textiles with low MOQ’s.

DYE

Dying fabric is a process of adding the desired color into raw material. Dying of the material takes place after the fabric has been knitted or after the garment has been made. Again, if the clothing manufacturer you work with is a full package company, they handle this part of the process.

COST OF DYE

The dying cost depends on the type of dye process, such as reactive, organic, and other specified dye you’ve chosen. Also, if you request treatments such as antimicrobial, dry-wicking, preshrink, or others, it will add to your cost. Finally, like everything else, the price will also be determined by the order quantity. For emerging brands, this can be tricky and expensive to do. Since some dye houses will have a high surcharge in addition to all of these costs. Keep in mind that all the textile mills on AVmade.com are vertically integrated. Our customization process gives designers the ability to get what they need with low MOQ, factory pricing, and no surcharge.

SPREAD

What is spreading? Spreading is the first process a clothing manufacturer does once they secure the textile before cutting your production. Spreading a clothing textile means:

- The person assigned to cut will revise the marker

- Check the material quality and consistency

- Then, start spreading across the cutting table

The number of layers (also known as plies) the cutter will spread will be based on the;

- The marker length size

- Cutting tickets for the quantity

Once the cutter has done spreading, the need to allow fabric to relax for a couple of hours before cutting. Relaxing a textile is an industry terminology that means leaving the clothing textile on the cutting table for a certain amount of time in case it was pulled during the framing or spreading process. A great cutter understands how crucial it is to relax the fabric before cutting. Spreading and relaxing will be essential to avoid fit issues once the garment is sewn. There is no added fee for this, as it is part of the cutting process.

CUT

Once the garment is spread and relaxed, the cutter will lay the marker over the fabric and begin cutting. Once the cutting part is completed, each size is bundled and tied separately to eliminate mix-up.

COST TO CUT

The cost of this process varies based on quantity, as most clothing manufacturers have a minimum charge. All clothing manufacturers structure their prices based on dollar minimums or dollars per clothing, whichever is greater. Again, if you are doing a full package, then the cost is embedded.

Minimum Vs. $ Per-piece charge.

If your production is small, you will pay the cutting house a minimum fee. Let’s give you an example. Say, Alex’s factory has a $150 minimum charge for cutting, and in their a la carte for large t-shirt production, over 300 units, cutting per unit cost is $0.50 a t-shirt.

Consider that it may be $0.50 per t-shirt if you’re doing 300 units or more. But otherwise, it will be $1.50 if you’re only producing 100 or $2 if you are doing 75 units. Also, note; there is no such thing as a fixed rate per all types of clothing since cutters will charge more or less depending on the complexity or simplicity of style. An example, a t-shirt has 5 pattern pieces such as a front, back, two sleeves, and a neckband, which is simpler and less time-consuming to cut than a denim jacket with up to 20 pieces. So minimums and per piece price will go much higher for the denim jacket vs. a t-shirt.

Also, the more delicate the clothing textile is to cut like silk, chiffon, or modal, the higher the price will be since it will take more time. It’s just basic math involving time. There are two ways a professional cutting service provider will charge–based on a minimum order or per piece price. Most garment cutting services have a $150 minimum charge on average. Once your production exceeds the minimum cost per piece, the price can range between $0.50-$5.

The lower price usually involves simple products, like a tank top, t-shirts, and other simple products. The higher price will be for blazers, gowns with many layers, and more complex things. The best way to think of this will be the more pattern pieces and delicate the textile, the higher the price.

All the clothing manufacturers on AVmade.com charge 60% less than other professional factories to help our brand partners to stay competitive.

Now we have the cutting out of the way, let’s talk about sewing clothes.

SEW

Sewing the cut pieces is part of the process that will finally bring the garment to life. Depending on the garment developed, the sewing involves joining the pattern piece to create the desired shape. Also, the type of sewing machine and sewing operators to be used will be determined based on the garment type. If a factory is accustomed to doing a t-shirt will not be the ideal clothing manufacturer to do a dress shirt and vice versa. We have elaborated on what it means to find the right manufacturers for your brand regarding experience and quality.

SEW COST

Like the cutting part of the process, sewing will depend on a few variables such as;

- Type of fabric, whether it’s delicate or not

- Quantity

- Complexity

- Deadline

- & whether or not you used a broke, full package facility, or a cut and sew factory

We keep being adamant that designers find and use a professional clothing manufacturer like those on AVmade.com who do full packages. It is vital for those building their rand to get competitive pricing, cut out the middlemen, and maintain high quality.

MAIN LABEL

What is the main label? The main label is what you’ll find on the back neck of the garment that states the brand name. Its purpose is simply for advertisements and for representing your brand.

There are many different ways the main label is made; here is a list of a few popular options:

- WOVEN

Woven label is then the most traditional and perhaps the oldest type of the main label in the apparel industry. The process includes a woven logo into a damask tape that looks like the picture below.

The downside of woven labels:

- Most require a high MOQ of around 1000+ units per size since setting up the machine to run production is labor-intensive. But our factory partners do offer woven labels of the highest quality as low as 100 units with no surcharge.

- Cheap woven labels will scratch the back of the customer’s neck.

- Poor quality can result in fonts that won’t be crisp since the stitching machine quality matters.

You can find woven labels being provided by many of the factories on AVmade as a past of customization with low MOQ and no surcharge.

- TWILL TAPE

Twill label is used mainly in the past 10-15 years and features a few advantages. The process involves printing your logo on either a twill tape or other type of ribbon-like material of your choice.

- Material choices range from satin, which is silky and shiny.

- Cotton tape for a natural look.

- Keep in mind that the max print colorway available by most suppliers outside of AVmade is two. But nearly all factories on AVednros.com offer print labels up to 6 colorways with a low minimum and no surcharge.

- TAGLESS

Tagless print is applied to products like t-shirts or athleisure wear brands. To accomplish this, you need to ensure that the garment-textile features a smooth surface like a t-shirt, legging, or similar fabric. There are two ways this can be accomplished,

- Heat Transfer: these tags work well on soft and smooth textures that are first engraved using ink on a plastic surface.

- Printed Directly: these tags are printed in the form of a silkscreen directly to the garment.

Both options are offered by most factories on AVmade.com with a low MOQ and no surcharge.

Factories’ prices on AVmade are 40-50% less than traditional full package manufacturers.

CARE LABEL

You will generally find a care label on the inside of most garments. They are located at the side bottom of your clothing towards the hip area. The label should include care instructions advising wearers on how to wash the garment. It consists of various symbols showing the type of material used, where it’s made, and other technical information. Its primary purpose is to be transparent with the customer and give an insight into how to care for clothing. Also, if a customer is allergic to certain clothing textiles, it can be used as an overall indicator of technical information. Every garment produced on AVmade.com has an incorporated care label with full details. It is provided for free for all of our brand partners.

TRIMS

Trims in the apparel industry include ornaments such as buttons, ribbons, zippers, strings, or other forms of decorations. It is usually not part of the textile. Instead, it is an ornament or an accessory used to enhance an article of clothing aesthetically, functionally, or both.

EX: A zip-up hoodie will be made of three different components.

- A french terry fleece = textile

- A zipper = trim for functionality

- A drawstring =trim for functionality and aesthetics

So by understanding the overall concept when evaluating clothing, you can quickly identify a trim. Depending on what you’re looking for, about 98% of the time, it is something that a full package clothing manufacturer will provide without you having to outsource it unless you are using a cut & sew factory. In addition, all factories on AVmade.com offer most trims free of charge.

QUALITY CONTROL (Q.C.)

QC’ing (Quality controlling) is a vital step when dealing with the clothing manufacturer. It is about the process the product goes through to ensure consistency with every garment. It refers to the clothing manufacturer’s ability to properly inspect the product quality throughout the production process before sending it out to the brand.

Each clothing manufacturer has a factory set AQL (acceptable quality limit) chart they follow, such as;

- C. fabrics on arrival

- Inspect while spreading for flaws

- While cutting to verify accuracy

- Inspecting the garment while being sewed

- Inspecting the garment after sewn

- Finally, an AQL ratio is set based on quantity. All our factory partners on AVmade.com do at least a standard AQL of 2.5 level II.

So each time, they can get ahead of a problem if there is an issue. AQL is a ratio of measurement tools used by clothing manufacturers to evaluate how much the production has progressed while maintaining its quality.

Finally, professional factories will do a final spec on all garments to prevent any garment from slipping through the crack on the finishing line.

FINISHING

Finishing is terminology used to describe the final part of the process once the garment is sewn. Which are,

- Trimming

- Pressing

- & packaging

It merely describes the end part of the apparel manufacturing process once all the production processes we’ve discussed above are completed.

- The trimming part of the process is where all the excess thread is trimmed correctly to ensure the garment is presentable and reflects the best quality the clothing manufacturer offers.

- Pressing means steaming & ironing the garments to accentuate their best features; This is aesthetically pleasing to the customers.

- On the other hand, the packaging is the last part of the process after being trimmed and pressed. Garments will then be folded and put in individual poly bags or without the polybag if customers want a sustainable/ eco-friendly option.

LEAD TIME

Production lead time varies based on the quantity and complexity of the style. The process based on AVmade factory partners’ is around 4-6 weeks unless the volume is high and you have an elaborate concept to add to the clothing. In that case, a little more time may be required. Most traditional factories in the USA are likely to take double that time and overseas factories around 12-18 weeks for standard production.