In the competitive fashion world, custom clothing makers are indispensable for making custom designs. Unlike wholesale clothing, custom clothing manufacturers produce apparel based on design specs provided by designers or obtained from brands and individuals. This approach enables each piece of clothing to achieve a high level of personalisation and rarity due to the developments in individual styles.

Custom clothing manufacturers play an essential role in addressing the gap between creativity and consumer demand. These manufacturers are vital to ensuring the availability of a lot of diversity and quality in products offered currently by the fashion market since it is through them that designers can achieve their goals. Custom clothing works both as a carrier of personal style and helps create a sense of unity between consumers and their clothes.

The Fashion Industry Trends

With the development of fashion, an evident trend is towards upscale designer products. Brands desire to discover exceptional products that will enable them to express themselves through the products they choose. This change has led to the emergence of custom clothing, creating a demand for manufacturers capable of converting designs into real clothes.

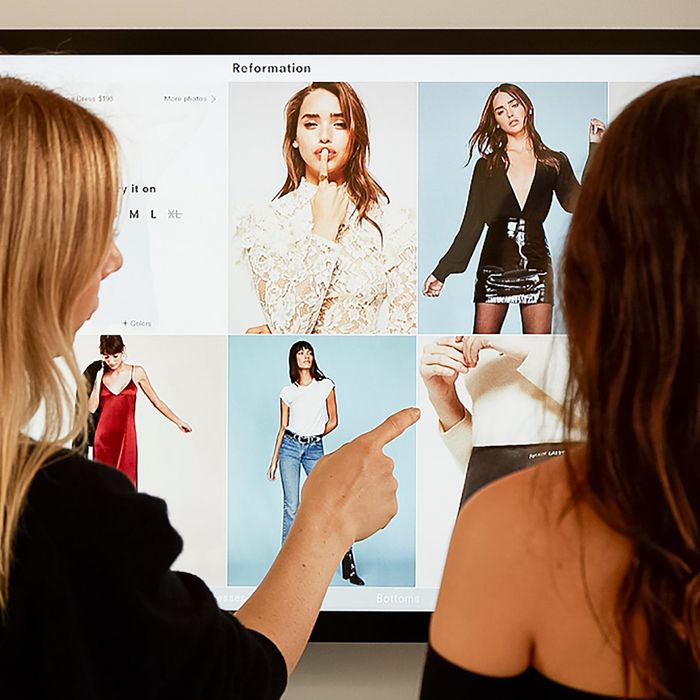

In addition, digital technology and online platforms have changed the fashion-consumer relationship. Customisation tools and virtual design studios have enabled individuals to engage actively in the clothes designing process, which accounts for increased requirements on custom clothing manufacturers.

The objective of the article

This article gives a general background of the custom clothing manufacturing industry, especially concerning AVmade. A novel avenue for collaboration arises when AVmade merges with designers’ needs. This paper discusses the nuances of tailored clothing production, revealing important concepts, categories of manufacturers and pros and cons in connection with AVmade. At the end of this article, readers will know how custom clothing manufacturing reflects AV trends as an informer to companies and designers about what happens in this industry.

Understanding Custom Clothing Manufacturing

Custom clothing manufacturing refers to making clothes according to requested standards per brands tastes and needs. This process outperforms generic apparel and provides impressive personalisation in fabric, design pattern fit, and ornaments.

The essence of custom clothing manufacturing is about specialised design, tailor-made production and integration of modern technologies in the stage of manufacture. All these contribute to the uniqueness and precision of bespoke clothing.

Types of Custom Clothing Manufacturers

Upscale or generic Manufacturers

Upscale workshops, if they are structured to assist small brands in custom clothing manufacturers, are the best options for local designers or small brands. These manufacturers are characterised by their precision and adaptability in addressing different brand specifications as well as agile manufacturing process and flexibility to help these brands threive. It’s best for short runs or luxury lines.

Mass Production Plants.

Mass manufacturers of custom clothes deal with the needs of more prominent brands and designers with a larger audience. These facilities apply advanced production technologies and cost-effective procedures to manage larger volumes without sacrificing customisation options.

Specialty Manufacturers (Eco-friendly, Sustainable, etc.)

The specialty custom clothing manufacturers target niche markets like eco-friendly practices. To this end, these manufacturers use sustainable materials and adopt ethical production practices in custom clothing manufacturing to respond to such a switch towards eco-consciousness. This section is directed towards filling the demands of customers who wish to be different and, at that same time, ecologically friendly.

Benefits of Selecting Custom Clothing Manufacturers

Choosing custom clothing manufacturers offers several advantages for designers and brands operating in the AV-made clothing industry:

- Uniqueness and Personalization: Custom manufacturers enable many unique designs for the central theme audiovisual ideas to stay memorable and individualised.

- Quality Control: As a rule, the customisation practice entails cooperation between designers and manufacturers, whereby they are obliged to maintain quality standards at different stages of production.

- Flexibility in Design: Custom manufacturers are prepared to respond to diverse design specifications, and they can adapt fabric colouring or design that will satisfy the creative needs of AV designers.

Prospective Challenges and Solutions.

While custom clothing manufacturing presents numerous benefits, there are potential challenges to be mindful of:

Cost Implications: The customisation process can lead to cost increments, especially for small-scale production. Budgeting and planning are crucial to overcoming this.

Communication and Collaboration Issues: Custom manufacturing requires effective communication. Creating a strong communication channel, using digital tools and coming up with prototypes can prevent miscommunication; hence, agreement is reached on the design specifications.

Production Timelines: Small Custom manufacturing might take more time than mass production. This challenge should be met with realistic schedules, early planning and coordination of production timetables.

Knowing such advantages and disadvantages allows organisations to manufacture clothing items in the AV-made clothes industry with judgement when selecting custom manufacturers for profitable cooperation.

Locating the Perfect Custom Clothing Manufacturer.

When choosing a tailor-made clothing manufacturer, one should consider the production capacity. AVmade specialises in the end-to-end manufacturing process for upscale clothing brands that need a well established factory to handle all their manufacturing needs and intricate design details. If you choose another factory to work with, make sure to analyse their machinery, technology adaptation and production capability to determine how well they can fulfil the distinctive needs of AV-inspired apparel.

Quality Control Measures

However, the importance of quality control is a determinant in Custom Clothing Manufacturing, especially where it meets specific needs unique to the AV industry. Quality control measures are easily verified by visiting the manufacturer’s past work and demanding certificates that attest to their zeal towards quality goods.

Reputation and Reviews

Find out the position of potential manufacturers in the AV-made apparel and garment industry. Their reviews, testimonials and case studies are available for their performance measurement and to check how credible they can be. The best potential partner is a manufacturer with proven success in executing creative visions and reaching deadlines.

Cost Considerations

Production Costs: Calculate the production costs of the selected custom clothing manufacturer. Costs for the clothing produced by AV should be based on design level, material type and scale of production. Assess the cost-efficient plan for each element without violating budget limits and undermining quality.

Additional Fees (Shipping, Customs, etc.): Additionally, consider other fees like freight and customs responsibilities. If a manufacturer is from a different country, import/export costs should be considered.

Communication and Collaboration

It is important to point out that collaborative communication requires integration. Select the manufacturer with well-defined and effective channels of communication. The manufacturing process runs smoothly due to regular updates, clear instructions and a responsive team.

Why choose AVmade?

One of the commonly used products by design makers, especially for AV-themed clothing, is made by made. Also, the AVmade garments have been designed with visual aesthetics in mind that incorporate creativity and technical knowledge. Their quality transparency and long-term cooperation with designers make them a perfect choice to partner in building AV-inspired clothing lines.

Custom Clothing Manufacturing Process

Work with our design team to establish the concept for your clothing brand and product designs. Indicate the thematic elements, material, fit, colour schemes and any unique audiovisual components that need to be included in the clothes.

Material Selection

Choosing the right textile that resonates with your brand aesthetic while being on par with most cutting edge model yarn is critical to building an upscale brand. AVmade mill most of the fabric for their brands and their ability to custom mill is unparalleled in the industry. It is important to collaborate with manufacturers who comprehend the best textile choice for your brands needs as that will make or break your brand.

Prototyping and Sampling

Prototyping offers the design embodiment, which can help identify any issues and improvements required before mass production. This phase is particularly crucial in the case of AV-produced clothing to ensure that audiovisual components are incorporated into the clothes.

Evaluating and Iterating Samples

Critically analyse the first samples and provide recommendations for improvement. The prototyping and sampling iterative process ensures that the final product captures the desired AV theme, a balance between creativity and functionality.

Mass Production

The shift from prototypes to full-scale production is a very well-thought-out process. Manufacturers should be able to scale up their operations without compromising the quality and fidelity established during the prototyping stage. Frequent communication is necessary to ensure that the end product is by the design that has been approved.

Quality Control along the Production Line.

Establish reliable quality control measures in all stages of mass production. Regular inspections, tests, and observations of quality standards are required for AV manufactured clothes to satisfy the needs of designers and consumers.